Dongguan jiachao hardware technology co., LTD

Contact person: Mr. He

Telephone: 13829137022

Telephone: 0769-8333 3591

Fax: 0769-8333 5379

Mail box: hejianguo@jiachao-tech.com

Web site: www.jiachaotech.com

Web site : en.jiachaotech.com

Address: yingshuo industrial park, no.59, tianheng road, shahukou village, changping town, dongguan city

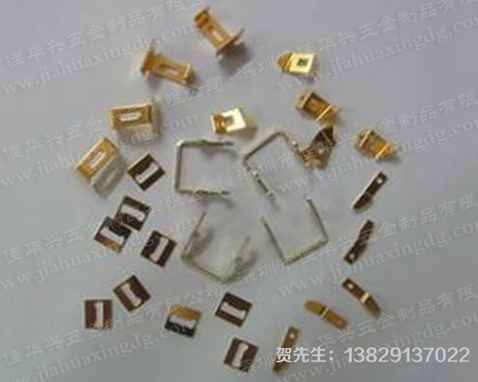

Metal stamping piece processing

Hardware stamping parts of the hardness test using rockwell hardness tester. Small, complex shaped stamping parts can be used to test surfaces that are too small to be tested on a standard rockwell hardness tester.

Stamping parts processing includes blanking, bending, drawing, forming, finishing and other processes. Stamping piece processing materials are mainly hot rolling or cold rolling (mainly cold rolling) of metal plate with materials, such as carbon steel plate, alloy steel plate, spring steel plate, galvanized plate, tin plate, stainless steel plate, copper and copper alloy plate, aluminum and aluminum alloy plate, etc..

PHP series portable surface rockwell hardness tester is very suitable for testing the hardness of these stamping parts. Alloy stamping parts are the most commonly used parts in the field of metal processing and mechanical manufacturing. Stamping parts processing is a method of separating or forming the metal sheet strip by means of die. Its application scope is very wide.

The main purpose of the hardness test of stamping parts is to determine whether the annealing degree of the purchased metal plates is suitable for the subsequent stamping parts processing. Different types of stamping parts processing technologies require different hardness levels of the plates. Aluminum alloy plate used for stamping parts can be tested by wechsler. When the material thickness is greater than 13mm, it can be changed to a barr durometer. Pure aluminum plate or low hardness aluminum alloy plate should use a barr durometer.

In the stamping industry, stamping is sometimes called sheet forming, but slightly different. The so-called plate forming refers to the forming method that USES the plate, thin-wall tube, thin profile and so on as the raw material for plastic processing, which is collectively referred to as plate forming. At this time, the deformation of the thick plate direction is generally not considered.